See the first installment of this series here.

Wedges for stick chairs must absorb a lot of shock so they don't snap when you install them. So I steer clear of weak (sycamore) or brittle (ebony) woods.

Most of my wedges are oak or ash, species that are plentiful and inexpensive. I don't think I've ever snapped an oak or ash wedge, even when I've struck them at odd angles. I have used walnut and cherry wedges at the request of customers. They work, but you have to be deliberate when hammering them in because they will snap.

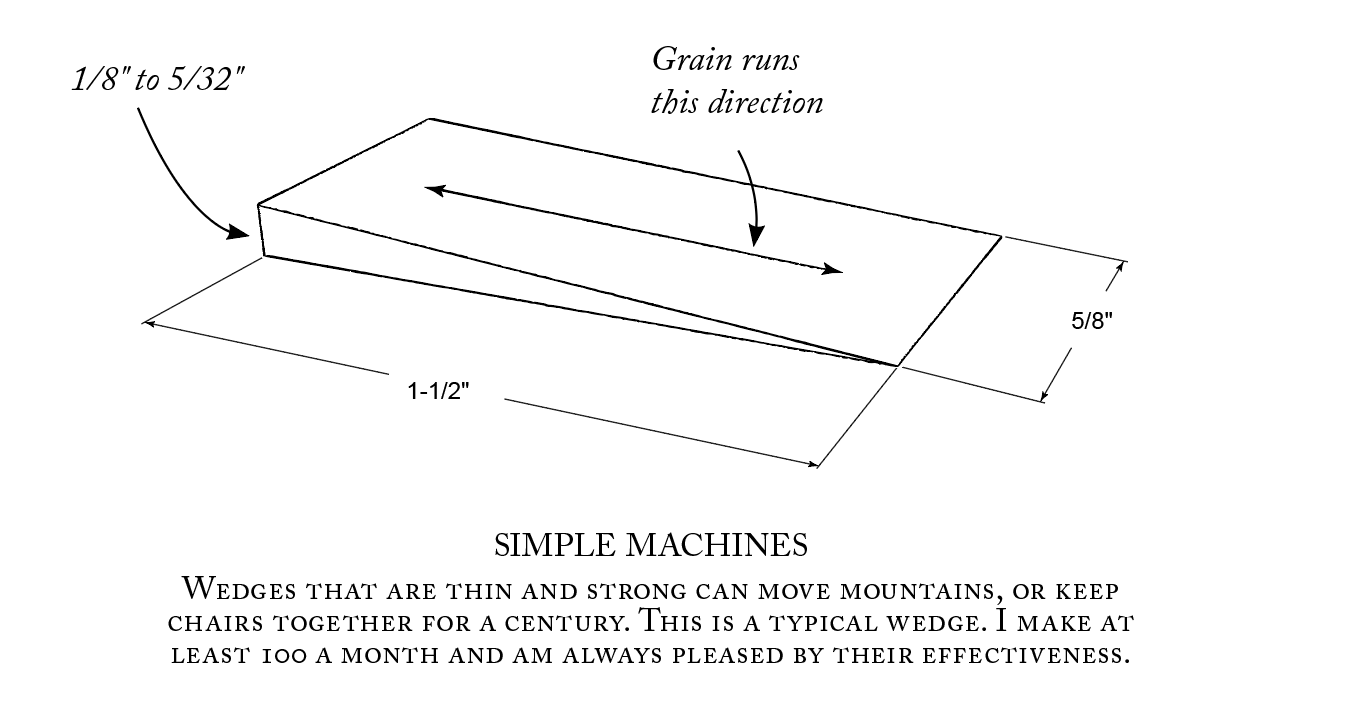

The grain in a wedge should run along its length, from its thin tip to its fat end. For chairs, I use wedges that are 1-1/2" long. The fat end is between 1/8" and 5/32" thick. The tip comes to a sharp point. If I need a blunt tip for some reason (say the tenon is loose and shallow), I'll snip off the pointiness.

A 1-1/2"-long wedge with a 1/8" fat end makes a wedge with a 4.8° included angle. A wedge with a 5/32" fat end has a 5.9° included angle. Both of these angles work fine. A wedge with a larger included angle can cause the wedge to bounce out of the tenon when you hammer it in. The solution is either to hit the wedge harder until the wedge hopefully grabs, or switch to a wedge with a smaller included angle.

Wedges with included angles smaller than 4° can work, but the wedge is more likely to snap off when struck.

Wedges With & Without a Sled

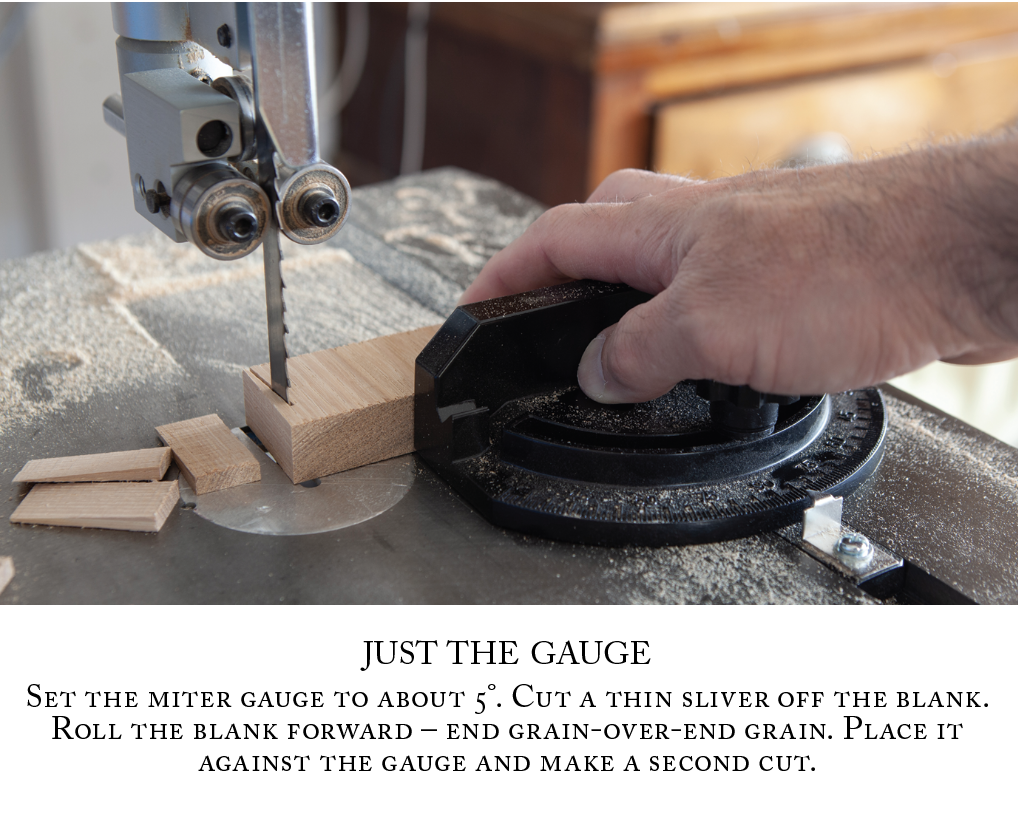

You can make wedges without a jig on the band saw by using the saw's miter gauge. Crosscut a 5/8" x 1-1/2"-long chunk off a board that is about 6" wide. Set the saw's miter gauge to cut 5° off 90°. Put the chunk on the miter gauge and cut off a thin sliver. Flip the chunk over – end grain-for-end grain. Slide the chunk toward the blade and make another cut.

You will quickly figure out where to place the chunk so that you make a perfect wedge. You can make wedges with thin points and blunt points.

Keep flipping the chunk over and over. Make wedges until your chunk is so small that it feels dangerous to make the cut while so close to the saw's blade.

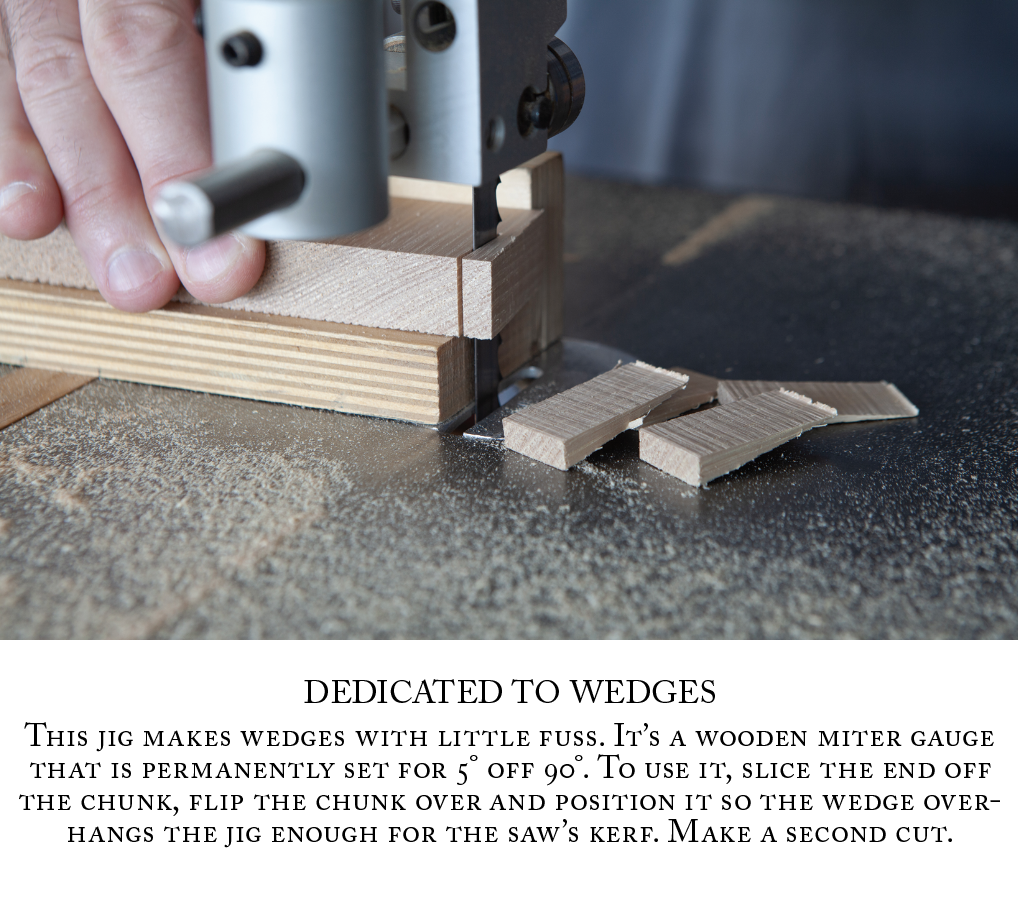

You can also make a dedicated wedge jig for the band saw's miter slot that has zero clearance to the blade. This jig is shown above. It is permanently set at 5° off 90° and makes it easy to position the chunk of wood and slice a perfect wedge.

The disadvantage to both of these miter-gauge methods is also its advantage. The technique makes it easy to make different wedges. By moving the chunk of wood left or right on the miter gauge, you can make wedges that are fatter or skinnier.

— Christopher Schwarz

No comments:

Post a Comment